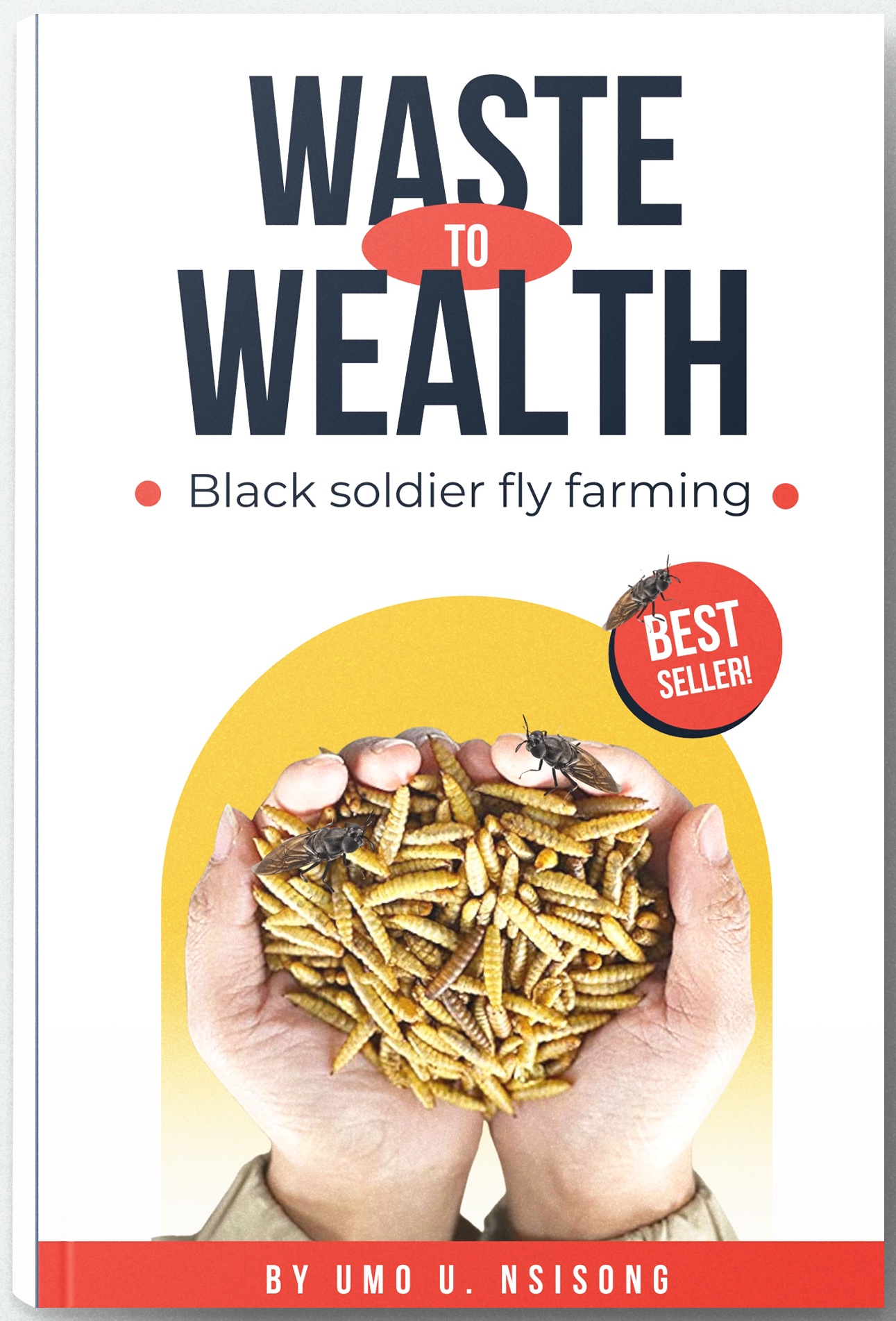

Book Preview

Part I: Foundations of Black Soldier Fly Farming

Chapter 1 – Introduction to Black Soldier Fly (BSF)

• BSF (Hermetia illucens) is a harmless insect, unlike the common housefly.

• Its larvae consume organic waste rapidly, turning it into nutrient-rich biomass

• A Short Life, a Big Impact

• A Global Movement Toward Sustainable Protein

Chapter 2 – Why Black Soldier Fly Farming Matters

• Environmental benefits: Reduces food waste, lowers landfill use, and cuts methane emissions.

• Economic value: Produces affordable feed for poultry, fish, and pigs.

• Social impact: Creates jobs, especially for youth and women in rural areas.

• Efficiency in Resource Use: Doing More with Less

Chapter 3 – Global Perspectives

• Africa: Growing adoption in Kenya, Nigeria, and South Africa for poultry and fish feed.

• Asia: Leading commercial farms in China, Indonesia, and Vietnam.

• Europe: Biotech companies are scaling up BSF farming under strict EU regulations.

• Americas: BSF being integrated into pet food and aquaculture industries.

Part II: Practical Farming Techniques

Chapter 4 – Getting Started

• Choose location with good ventilation, waste availability, and security.

• Deciding the Scale of Your BSF Farm

• Indoor Vs outdoor BSF farming

Chapter 5 – Understanding the BSF Lifecycle

• Eggs hatch in 4–6 days.

• Larvae (the most valuable stage) eat organic waste for 10–14 days.

• Pupa stage is the transition before adulthood.

• Adult flies live 5–8 days, mate, and lay eggs — they don’t eat, only drink water.

Chapter 6 – Feeding the Larvae

• Best feeds: fruit and vegetable waste, food scraps, brewery by-products, animal manure.

• Avoid toxic or oily waste (chemicals, plastics, heavy metals).

• Larvae can reduce waste volume by up to 60%.

• Feed conversion ratio: 1 kg of waste produces 200–250 g of dry larvae.

Chapter 7 – Building Infrastructure

• Breeding cages for adult flies.

• Small containers for egg hatching and larval growth.

• Larger bins or trays for mass rearing.

• Simple harvesting tools (sieves, buckets) or automated conveyor systems.

Chapter 8 – Harvesting and Processing

• Harvest larvae at the prepupal stage for maximum protein.

• Dry or roast larvae before grinding into meal.

• Extract oil for feed or industrial uses.

• Collect frass (larval manure) for organic fertilizer.

Part III: Products and Markets

Chapter 9 – Products from BSF Farming

• Protein meal (42–55% protein) for poultry, pigs, and fish.

• BSF oil rich in lauric acid for animal health.

• Frass as a natural organic fertilizer.

• Chitin from exoskeletons, useful in medicine and industry.

Chapter 10 – Market Opportunities • Poultry feed mills and fish farms.

• Pet food industry (dogs, reptiles, aquarium fish).

• Organic fertilizer markets.

• Export opportunities for dried larvae and BSF meal.

Chapter 11 – Business Models

• Smallholder: rearing BSF for personal poultry/fish.

• Cooperative model: shared infrastructure for community farmers.

• Large-scale: commercial farms supplying feed industries.

• Integrated model: combining BSF with aquaculture or poultry farms.

Part IV: Sustainability, Challenges, and the Future

Chapter 12 – Environmental and Social Impact

• BSF farming diverts food waste from landfills.

• Helps farmers cut feed costs by up to 30%.

• Empowers communities with new income streams.

Chapter 13 – Challenges in BSF Farming

• Lack of awareness and training.

• Seasonal challenges (temperature, humidity).

• Limited regulations and market acceptance.

• Need for funding and technical support.

Chapter 14 – The Future of BSF Farming

• Growing recognition by FAO, World Bank, and NGOs.

• Potential to replace fishmeal and soy in animal feed.

• Expansion into pharmaceuticals and biomaterials.

• Technology-driven farms with AI, sensors, and automation.

Part V: Practical Resources

Chapter 15 – Step-by-Step Startup Guide

• Budget estimates for small, medium, and large farms.

• How to source BSF eggs or starter kits.

• Building a pilot farm before scaling up.

• Tips for maintaining healthy colonies.

Chapter 16 – Case Studies and Success Stories

• Nigeria: Small farmer turns waste into chicken feed.

• Kenya: Commercial farm supplying feed to aquaculture industry.

• Europe: High-tech farms scaling protein production.

• Asia: Integration with municipal waste management systems.

Chapter 17 – Tools, Suppliers, and Networks

• List of equipment suppliers.

• Global BSF associations.

• NGOs and funding opportunities.

Chapter 18

• Sample grant cover letter

• Sample grant proposal

• Sample business plan

Be the first to review “Black Soldier Fly Farming”